Recommendations for Storage of Urea or Diesel Exhaust Fluid (CH4N2O)

Urea (also known as carbamide, carbonyl diamide, diaminomethanal, or DEF) is a chemical widely used for agricultural, industrial, pharmaceutical and for the manufacture of urea formaldehyde resin used in plywood products. The two most common uses today are for agricultural fertilizers, as urea provides an excellent nitrogen source, and as a constituent of diesel exhaust fluid (DEF), which is 32% urea and 68% reverse osmosis (RO) water and is commonly used for reducing nitrous oxide (NOX) in diesel emissions.

Technical Specification for a Urea Tank:

Cross-link or linear polyethylene. Cross-link is preferred for longevity, durability and safety. Tank must be rated at a minimum of 1.5 specific gravity. Based on a common specific gravity chemical of 1.14. Stainless steel and fiber reinforced plastic (FRP) are often used for larger vessels.

- Fitting Material:

PVC or polypropylene for nozzles - Gaskets:

EPDM material - Bolting Hardware:

316 stainless steel - Special Considerations:

Proper venting; Heat tracing and insulation for outdoor storage applications

Secondary Containment

All end users should check local regulations to meet secondary containment requirements. Containment must be adequate in capacity and suitable for urea. Double wall type tanks or secondary containment basins should be sized typically to 110% of the primary tank’s capacity. By accepting the delivery of the tank, the customer accepts full responsibility for providing appropriate and adequate containment for the stored material. Eastern Reliability offers a variety of secondary containment basins.

Connections

Bulkhead style connections can be used on tanks 2,000 gallons and below. Tanks above 2,000 gallons sidewall connections should be flange type construction. Sidewall connections should be installed a minimum of 7" above the tank floor. Internal siphon drains can be used if required. There are no restrictions on dome fittings. On double wall type tanks 316 stainless steel outlet connections are required.

Sidewall connections should be installed a minimum of 7" above the tank floor. Internal siphon drains can be used if required. Sidewall connections should be kept to a minimum amount and should be placed no closer than 22° apart. Whenever possible, sidewall connections should not be greater than 3". There are no restrictions on dome fittings.

Flexible Hoses or Expansion Joints

Flexible hoses or expansion joints must be used on all lower ½ sidewall connections. A lightweight isolation valve is permitted prior to the flexible joint. Nipple and valve weight must not exceed 8 lbs. All piping must be supported independent of tank. Pipe supports must be installed after the flexible joint to allow the tank to expand and contract under normal service conditions. Polyethylene tanks expand and contract both laterally and vertically, the expansion hose or joint must accommodate for this expansion.

Tank must maintain atmospheric pressure. Vents must be sized for a minimum of two times the largest inlet or outlet port for pneumatically or pump filled tanks. Adequate venting must always be maintained. Under no circumstances should tank be placed under pressure or vacuum conditions. Special considerations should be taken during venting and air intake into the tank to prevent dust or debris from entering the tank. A vent breather system like an automotive air filter should be considered.

Heat tracing and insulation should be considered on urea application when storage conditions fall below 32°F. Process cooling may be required to lower the temperature of urea above 90°F for process effectiveness and efficient chemical reaction.

Temperature Control

Diesel Exhaust Fluid (DEF) storage tanks require temperature control to prevent contamination and maintain the quality of the DEF, which freezes at temperatures below 12 degrees Fahrenheit (-11 degrees Celsius). It can degrade when exposed to high temperatures. The tank should be designed to maintain the temperature of the DEF between 32 and 77 degrees Fahrenheit (0 and 25 degrees Celsius). The tank should also be equipped with a temperature sensor that can detect any fluctuations in temperature and alert the operator if necessary.

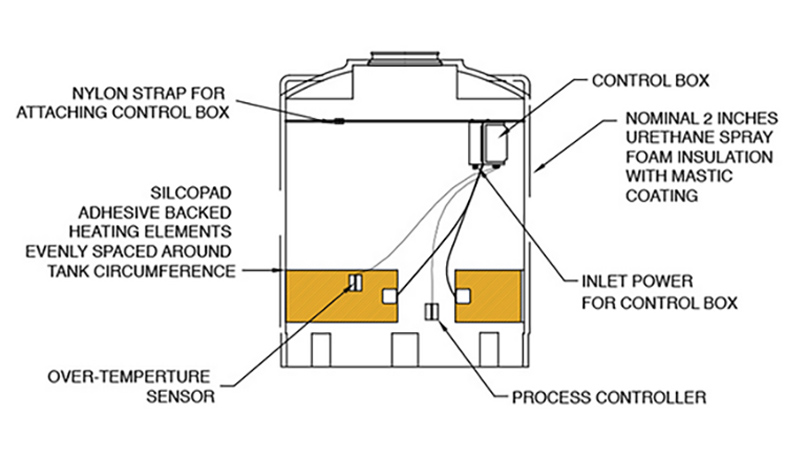

Eastern Reliability can customize your tank with a heating system to maintain the level required for DEF. The simplest system is where we wrap the tank with water-resistant, adhesive-backed heat tracing elements and cover them with a two-inch thick layer of polyurethane foam insulation and two coats of mastic. A control panel regulates temperature measured by high-level and maintenance-level thermostats set to desired limits. Using different heat tracing elements, the temperature can be maintained at any point above 50°F, 80°F, or 100°F over the lowest ambient temperature to which the tank is subjected. There are many more options to heat tanks that can be found here. We also have many years of experience in supplying electric pipe tracing systems to go along with heated tanks where necessary.

Delivery

All deliveries must be regulated. Maximum delivery pressures must not exceed 12 PSI. Under no circumstances should tank be placed under pressure or vacuum conditions.