Ultrasonic Level Sensing Systems

Ultrasonic-level transmitter systems are used for measuring the level of liquids using high-frequency sound waves to determine the distance between the transmitter and the surface of the material being measured. Ultrasonic-level transmitter systems are widely used in various industries such as water and wastewater management, chemical and petrochemical processing, food and beverage processing, and many others.

They are preferred over traditional level measurement methods due to their accuracy, reliability, and ease of use. Additionally, ultrasonic-level transmitter systems are non-contact and do not require maintenance, making them ideal for use in harsh and hazardous environments. The measurement is then transmitted to a control system, a display device, an alarm, or a combination of all, allowing for real-time monitoring of the material level.

Eastern Reliability has developed a packaged system that includes the sensor, controller, and all the other accessories that are needed to quickly get a system running. Not only can we customize the components of the system to your specific application, but we can also preprogram the sensor and controller based on your tank specifications so that the unit is plug-and-play right out of the box.

Ultrasonic Transmitter

Ultrasonic level transmitters provide continuous level measurement up to 39.3' with a 4-20mA analog output signal and can be configured via an integral push button display module. The non-contact Reflective Technology delivers reliable level measurement in condensing environments.

It is ideal for bulk tanks with non-foaming or mildly vaporous media such as chemicals, water, wastewater, and oils. Typical application areas include bulk storage, neutralization tanks, clarifiers, and waste sumps.

- Measuring Range: 19.6' or 39.3'

- Reflective Technology, Reliable Measurement even with Condensation

- Corrosion Resistant PVDF Transducer

- Narrow 3" Beam Width for Applications with Limited Space

- Fail-safe Diagnostics with Selectable Signal Fail-safe Outputs

- LCD Display Indicates Level in Inches, Meters, or Percent of Span

- Configuration via Push button Display or NEOCal Software

- Automatic Temperature Compensation from -40 to 176°F

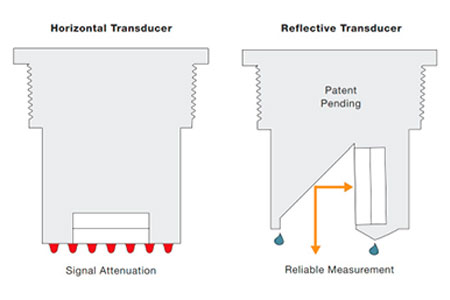

Reflective Technology

Condensation is the most common variable in liquid level applications. Condensation attenuates the acoustic signal of ultrasonic sensors with horizontal transducers, weakening their signal strength and signal to noise ratio by up to 50%, substantially reducing their measurement reliability. At the core of Reflective Technology is a simple principle. Unlike fat horizontal surfaces, significant water droplets cannot adhere to smooth vertical surfaces.

By orienting the transducer vertically, the condensation runs off the transducer and does not affect the sensor performance. The unimpeded transmit and receive signals are redirected to and from the liquid off a 45° reflector, delivering reliable level measurement.

Configuration

In addition to the push button display module, the sensor may be configured via our NEOCal software and one Fob USB adapter. NEOCal is a PC utility program that allows users to easily configure their sensors, update firmware, save configurations, and print wiring schematics prior to installation. You can also hook into the panel meter on box with a micro-USB to USB-A cord as an alternative to setup sensor parameters. The configuration software will be prompted to download when the connection is acquired. DO NOT connect micro-USB cord to unit while plugged into 110v power supply.

Ultrasonic Display

e PDA2300 series of economical plastic NEMA 4X enclosures for 1/8 DIN Digital Panel Meters provides a convenient way to mount up to ten Meters to walls and other vertical structures. Many of these enclosures also have room for additional devices like a light / horn and a 24 V transmitter power supply. Sub-panels are available to mount additional devices to the base of the enclosure. The meter is mounted in the door of the enclosure thus allowing for programming and operation of the meter. Mounting hardware is provided.

The door is hinged and secured with stainless steel latches. Standard enclosure setup comes with metering display with 4 relays, a stack light with red, yellow, and green colored indicators. There is an 80db alarm triggered when the ultrasonic sensor shows tank at full capacity that is tied into a reset button located on door to silence alarm after being triggered.

Features

- House up to 10 Meters

- Plastic

- 1/8 DIN Cutout(s) Pre-Cut

- NEMA 4X

- Hinged Door

- Stainless Steel Cover Latches

- Meter Mounted in Cover

- Sub-Panels Available

- Mounting Hardware Provided

- UL Listed

- Light / Horn & Reset Button