Tank, Pipe, & Valve Heating

When your storage or processing tank needs heating capability, we have the heating solution for you. Over-the-side, L-shaped, or bottom, flanged heaters or heat transfer panels can be retrofitted to your existing tank or added to a new system. Our electric heating solutions can be applied to tanks that serve the chemical, food, wastewater, dairy, pharmaceutical, brewing industries, and many other applications.

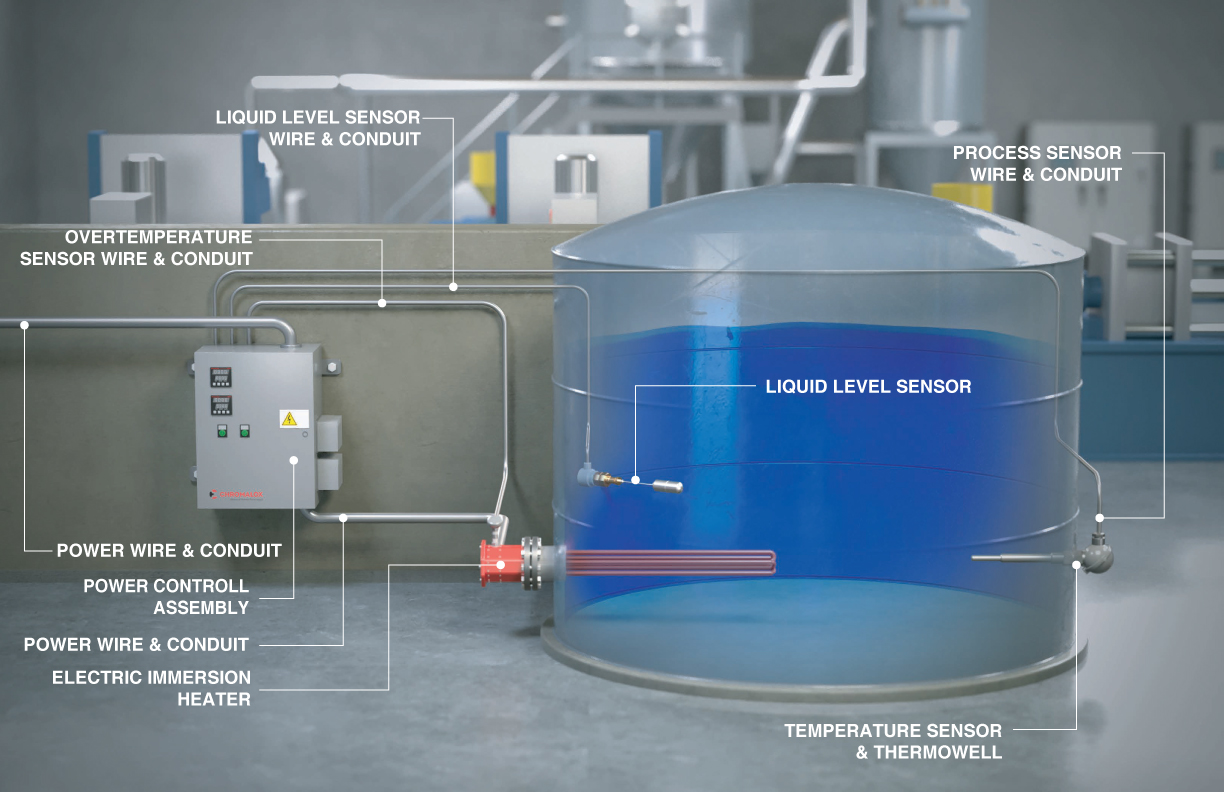

Specifically, when specifying heaters for all tanks, especially polyethylene, things to keep in mind are:

- Tanks should always have a liquid level sensor to shut off the heater as the hotter the solution gets the more expansion takes place and the greater the likely hood of a fractured tank.

- Acids cause corrosion and buildup on the heater sheath, which can cause overheating and heater failure. If the fluid is thick and viscous, low watt density is acceptable, whereas light oil could tolerate sheath watt densities to 30 W/sq. in. to 40 W/sq. in.

- Temperature control and liquid level sensors are a must-have in any plastic tank as if there is tank failure (i.e. solution empties from the tank) then the level safety device will shut the heater off safely.

Due to the precise control of temperature and heat distribution required for liquid storage conditions, electric tank heaters are usually the most cost-effective in storage tank applications. Each industrial heater solution is designed for the specific application and optimized to ensure high performance results as we must account for temperatures, viscosity of the fluid, corrosive nature of the fluid, tank insulation, and the overall operating conditions and project requirements.

Direct and Indirect Tank Heating

There are two main methods to tank heating: direct and indirect tank heating.

Direct Tank Heating

Direct tank heating consists of putting the heater in direct contact with the heated medium by placing the heater directly in the tank or circulating the fluid directly through the heater. The advantage of heating directly is that the heaters are nearly 100% efficient with this method. This is because all heat that is generated is absorbed directly by the process. This helps to speed heat-up and eliminate thermal lag.

Indirect Tank Heating

Indirect tank heating uses a heat transfer medium to transfer the heat to the tank. Indirect methods can vary from external heating of the tank using the tank wall as the heating medium to utilizing a heat transfer medium to carry the heat to the tank.

In addition, pipe insert heaters have been included in this category because they use an air space between the element and the process to convey the heat. There are various advantages to indirect heating. The biggest advantage is that the heater can typically be serviced without draining the tank. Second, indirect heating often allows watt density exposed to the process fluid to be lowered by spreading the heat over a larger surface.

We Offer a Full Range of Products for Any Tank, Pipe, or Valve Heating Application.

- Immersion and circulation heaters

- Heat trace products

- Hot water/oil steam boilers

- Insulated and heated tank blankets

- Class 1, Div. 2 heaters

- Corrosion resistant heaters

- Tank heater

- Heated valve covers

- MI cable

- Heat transfer systems

- FRP tank heating panels

- Epoxy laminated heating panels (flat foil resistive elements)

- Premium warranty

- Controls and sensors

What information do I need to calculate the size heater that I need for my application?

When it comes to tank heating the first step need to be a discussion with your Eastern Reliability sales engineer. There are no hard and fast variables for tank heating as every application is different so we will discuss what you need is and only ask you to get the 4 or five things necessary for your project versus giving you a list of 30 items for you to research that may not apply to your application.

Pipe & Valve Heating - Electric Heat Tracing

Heat tracing is used to counteract the heat lost from process equipment and piping through its insulation. A heat tracing system is a group of process equipment and piping, which is heat traced and controlled in a logical and economical manner. When industrial process piping and vessels must be maintained above the ambient air temperature, electric heating cable is the best solution for this application. Cables range in the maximum maintenance temperature from 150°F for self-regulating to 1100°F for mineral-insulated cables.

Self-regulating heating cables provide safe, reliable heat tracing for freeze protection of pipes, valves, tanks, and similar applications and are approved for use in hazardous locations.

Constant wattage heat trace cables are ideally suited for applications where a particular watt density is required at all times as it is an ideal choice for higher-temperature applications where higher watt densities are required.

Mineral-insulated heating cables are the most rugged heating cable product as they are constructed of a solid series resistor element embedded in highly compacted mineral insulation. MI cables are built to handle high-temperature, high-wattage applications.

Industrial Heat Trace Cable Applications

- Pipe freeze protection

- Process pipe temperature maintenance

- Hot water maintenance

Thermal Loop Management Diagram

Keep Your Valves and Pumps Protected

Most valves and pumps are built to last a long time and can withstand considerable fluctuations in temperature. However, if the valves/pumps in your piping or tank system are exposed to extreme cold for a prolonged period of time, extreme cold can affect their functionality in a serious way.

To prevent freezing in pipes, valves, manifolds, and instrumentation, we tailor our custom and off-the-shelf pipe and valve heaters to fit exactly around your valves, manifolds, and instrumentation. These heaters provide durable insulation and evenly distributes consistent heat and are easy to install and remove when necessary.

Using electric heating blankets is the most cost-effective way to manage heating valves and pumps as the installation cost is very reasonable. And we can design in a thermostat so that it can apply instant heat and only operate when needed.

We work with our sister company, Liberty Electric Products, which has more than 40 years of experience in electric heating solutions for chemical and industrial tanks. We will work with you to design the most cost-effective heating system for your application after we discuss with you the specifics of the project. Working with one company on the tank and the heater provides our customers with one point of contact to ensure that the project goes smoothly.

What’s My Freeze Point?

| Substance | Freezing Point | |

|---|---|---|

| Celsius | Fahrenheit | |

| Butane | -140 | -220 |

| Carbon Dioxide | -78 | -108 |

| Chloroform | -63.5 | -8.3 |

| Chlorine | -101.5 | -151 |

| DEF | -11 | 12.2 |

| Diesel (begins to gel) | -6 | -21 |

| Ethanol | -114 | -173 |

| Gasoline (begins to gel) | -40 | -40 |

| Gear and Hydraulic Oil | -23 | -10 |

| Glycerol | 17.8 | 64 |

| Helium | -272.2 | -458 |

| Hydrogen | -259.1 | -434 |

| Iodine | 113.7 | 237 |

| Mercury | -38.8 | -38 |

| Motor Oil 10W30 | -20 | -4 |

| Motor Oil 15W30 | -55 | -67 |

| Nitric Acid | -42 | -44 |

| Nitrogen | -210 | -346 |

| Propane | -188 | -306 |

| Sea Water | -2 | 28 |

| Sulphuric Acid | 10.3 | 51 |

| Water | 0 | 32 |