Specifying Proper Ancillary Equipment for Chemical Tank Applications Webinar

Specifying a tank for an industrial or chemical application not only includes determining how many gallons of a particular solution needs to be stored, but it also includes a whole host of ancillary equipment that may be required to ensure that your application objectives are met.

Not only is it important to understand how to specify these correctly to get exactly what you need, but we will also discuss the different options for each so that you can choose the proper solution that fits in your budget.

In this webinar we review many of the options that are either required to be put on a tank due to its application or equipment that is optional but necessary to meet your storage and safety requirements.

Webinar Agenda:

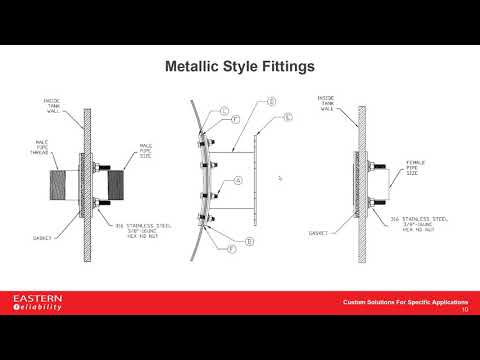

- Fittings (outlets, flanges, lifting lugs, etc.)

- Level Indicators and Other Instrumentation

- Heating and Heat Trace

- Insulation

- Ladders and Mixer Stands

- Leak Detection Equipment

- And a few others

Webinar Q&A:

At the conclusion of our webinar, we had several questions submitted to our presenter. We compiled these into a readable format listed below.

Question: Are your other tank manufacturers, other than Assmann, as flexible in design and offer just as many options?

Answer: The short answer to that is yes. The longer answer is All Assmann tanks, Justin Tank at Plastic Concepts, they all have virtually the same capabilities to ensure we're meeting what your design requirements are. So, yes, everyone has the capabilities to provide all those different types of fittings, where you need it on the tank, as well as if it requires a stand or an agitator support on the tank itself. That is all something all of our manufacturers are capable of doing.

Question: If I was trying to mix a sodium hypochlorite solution, what is my best option for mixer when it ends?

Answer: We work very closely with Cleveland Mixer and they as well have a wide variety of capabilities for storing sodium hypochlorite. I've done this a few times recently, and that would be either to provide a titanium shaft and impellers. Or another cost-effective solution is a PVC-coated stainless-steel shaft.

Upcoming Webinars: