Chemical Feed Stations

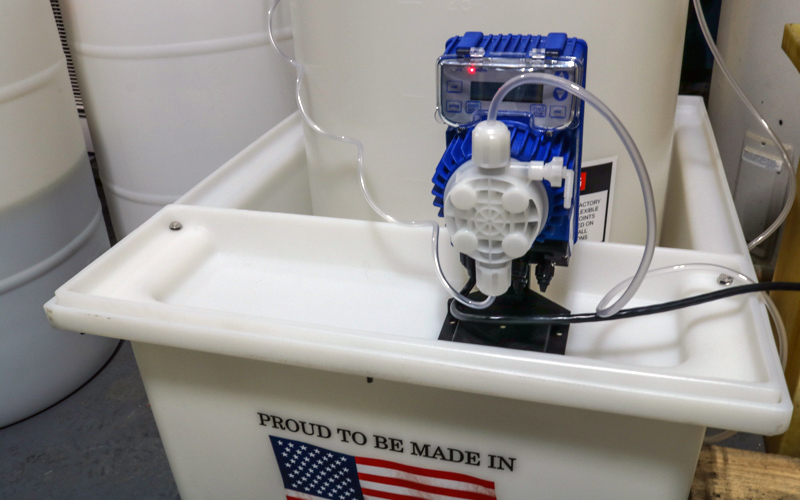

Our complete, ready-to-use, lightweight, easy-to-handle, and self-contained NSF-approved chemical feed stations with overflow basins allow you to dispense small amounts of liquids very accurately and without the handling costs and inconvenient disposal of drums. Our custom designs allow us to add features such as molded pump shelves, polyethylene primary tank stands, custom design fittings, level sensors, dosing pumps, and other accessories to individualize any customer's needs.

The tanks, catch basins, and other features of the chemical feed stations are constructed from high-density cross-link polyethylene or FDA and ANSI/NSF61-compliant, high-density linear polyethylene. The final result is lightweight, easy to handle, and self-contained. You can add on features such as molded pump shelves, polyethylene primary tank stands, custom design fittings, and accessories according to your needs.

Please contact us today with your specific needs, so that we can design the best solution to your challenge.

Compact, Complete and Ready to Use

Chemical feed stations, also known as chemical dosing systems or chemical injection systems, are used to accurately and reliably add chemicals to water or other process fluids.

Simple chemical feed stations are typically used for a variety of purposes such as:

- Water Treatment: Chemical feed stations can be used to add chemicals such as chlorine or other disinfectants to water to ensure that it is safe for consumption.

- pH Adjustment: Chemical feed stations can be used to add acids or bases to water or other process fluids to adjust the pH level.

- Chemical Dosing: Chemical feed stations can be used to add precise amounts of chemicals for a variety of purposes such as corrosion control, scale inhibition, and coagulation.

- Waste Treatment: Chemical feed stations can be used to add chemicals to wastewater to treat contaminants before it is discharged.

Our technical expertise in engineered system design with integration of turnkey modules for environmental enclosures helps you develop fully transportable and easy-to-install solutions for your chemical dosing applications.

Eastern Reliability Offers

Self-Contained Tank with Secondary Containment

Lightweight and easy to handle, the self-contained chemical injection tanks add to the complete ready-to-use design. Customers can add fittings and stands to the design and then incorporate their own components into the system. The primary tanks are semi-transparent, the containment basins are capable of holding 110% of the primary tank, optional pump shelves are available, easy-to-read volume markers and there are multiple lids available for either vented or fume-tight applications.

Custom Fully Assembled Systems

These systems include the self-contained tank and secondary containment along with one or any combination of the following:

- Dosing/Metering pumps - primary and secondary

- Mixers or agitators

- Overflow or low volume meter/alarm

- Leak detection

- Level sensing with outputs to control continuous flow of material

- pH and ORP sensors

- Remote monitoring

- Tank heaters

Our compact, reliable, and economically-priced system meters a single chemical into a tank or process line. The simple chemical metering system is a prepackaged skid that will arrive at your facility with all of the components installed and programmed so that you can quickly get up and running. All our fittings, instrumentation, and other components will be specified for each specific application depending on the chemical and operating environment involved.

Assmann Feed Stations

Assmann feed stations allow you to handle small amounts of liquids and other chemicals without the handling costs and inconvenient disposal of steel drums.

- Lightweight, easy-to-handle.

- 35 gallons up to 500 gallons.

- Uniform wall thickness allows the entire surface to cure evenly for a stronger tank.

- Air-cooled for a more uniform resin cure, reduced wall stress and improved shrinkage parameter for more consistent quality, greater structural integrity, and longer life.

- Primary tanks are semi-translucent.

- Basins can hold a minimum of 110% of the primary tank (Check local regulatory agencies for compliance in your area).

- 16” threaded lid with removable 6” air breather, open-top or hinged lids available.

- Easy-to-read volume markers.

- Polyethylene pump shelf supports most pumps and metering devices. Optional fiberglass shelves are available for pumps and metering devices totaling 25 pounds or more if required.

- Polyethylene tank stands, which may be stacked 2-high, will support the primary tank for gravity feed if required for an application. These can be placed inside the containment basin if required.

Durable, Reliable Polyethylene Chemical Feed Stations Are Designed with Your Convenience and the Environment in Mind

Customize an Assmann polyethylene chemical feed station to your needs with these and other options:

- Primary tanks in corrosion-resistant crosslinked polyethylene.

- Primary and secondary containment tanks in many colors.

- Fittings in a variety of sizes and materials to fi t your requirements.

- Adhesive-backed decals with your company name and logo.

- Dosing pumps (Diaphragm and Peristaltic).

- Level sensors, alarms, drain valves, and other instrumentation.

- Mounted on a skid if required with customized piping requirements.

- Mixers or agitators.

- Redundant pump setups.

- Immersion heaters or heat trace.

| Model Number | Capacity | Length | Width | Height | Primary Tank Access Openings | |

|---|---|---|---|---|---|---|

| US Gallons | Liters | |||||

| CFS 40 | 40 | 151 | 32 | 26 | 38 | 16 |

| CFS 60 | 60 | 227 | 47 | 32 | 42 | 16 |

| CFS 80 | 80 | 303 | 47 | 32 | 49 | 16 |

| CFS 140 | 140 | 530 | 52 | 38 | 58 | 16 |

| CFS 175 | 175 | 662 | 60 | 43 | 51 | 16 |

| CFS 200 | 200 | 757 | 60 | 43 | 57 | 16 |

| CFS 250 | 250 | 946 | 72 | 43 | 69 | 16 |

| CFS 300 | 300 | 1136 | 72 | 43 | 82 | 16 |

| CFS 550 | 550 | 2082 | 83 | 64 | 82 | 16 |

Model number availability and individual specifications subject to change without notice. Gallonage, weights approximate. All wall thicknesses conform to ASTM D-1998. Consult factory.

We have off-the-shelf units that you can buy and assemble the components yourself or we can provide you with the complete package; we customize for you.

Choosing The Right Dosing/Metering Pump for Your Chemical Feed Station

Diaphragm metering pumps are best in applications where you need to pump clean, aggressive chemicals into high-pressure systems, and require very little maintenance. Whereas Peristaltic metering pumps work best when you have “dirty” fluids that contain trapped gases or particulate matter liquids that need to be pumped into lower pressure systems.

Diaphragm Pumps

Solenoid actuated (electronic) diaphragm metering pumps are the most economical option in applications for low-flow/low-pressure chemical-dosing applications.). They offer a repeatable dosing accuracy of +/-3 percent. They are normally provided with an onboard relief valve to prevent pump damage from over-pressurization. Powerful microprocessor technology guarantees dosing accuracy, while wall and base-mounting options, constant and proportional dosing, and analog and digital variants provide unrivaled choice.

The use of premium materials such as PVDF and food-grade PTFE in the liquid end components gives our solenoid dosing pumps the flexibility to be used in multiple applications, as they have high resistance to a variety of aggressive chemicals including highly corrosive substances such as acids. With just a single moving part, these diaphragm pumps are virtually wear-free and require no lubrication of bearings or shafts, minimizing maintenance requirements and repair costs while offering excellent continuous-running characteristics.

Peristaltic Pumps

Peristaltic chemical metering pumps give users a unique advantage over diaphragm metering pumps as they can deliver at flow rates that remain constant right up to 100 psi and they eliminate the need for ancillary equipment while ensuring accurate, linear, and repeatable metering across all process conditions.

This pump technology, simplistic in its design, is perfect for handling viscous and abrasive chemicals. Because the design features a rotor with shoes or rollers that squeeze the hose or tube and force the liquid to the discharge port, peristaltic pumps are able to run dry and do not have valves that can become clogged. Every model in this range of automatic dosing pumps is IP65 rated for dust tightness and resistance to water jets and includes premium-grade Santoprene and SekoBril tubing as standard, providing long life and exceptional chemical compatibility.

A plethora of other tubing options are available for the safe pumping of aggressive fluids in the most severe applications. Outstanding dosing accuracy is achieved via intuitive analog and digital control along with high-precision stepper motors (certain models), while the user-friendly design means accessing, inspecting, and replacing peristaltic tubing is quick and easy.

Overall, the choice of metering pump will depend on the specific application requirements and the characteristics of the chemical being dosed.